Description

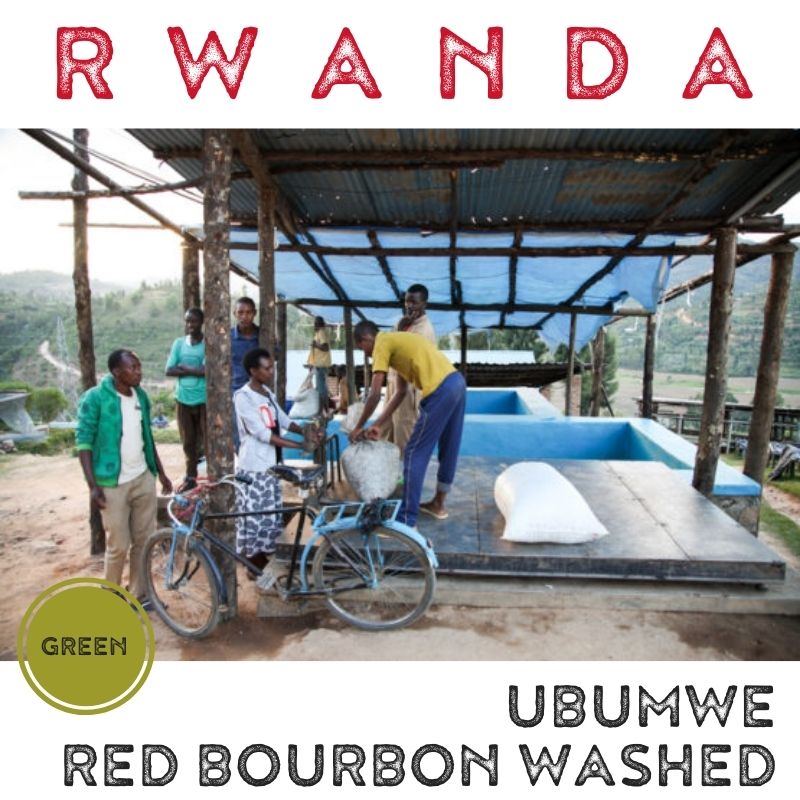

District: Karmonyi District, Gacerabwenge Sector, Southern Province

Altitude: 1550-1700 metres above sea level

Variety: 100% Red bourbon

Processing: Fully washed

Washing Station: Ubumwe

Owners: Epiphanie Mukashyaka of Buf Coffee

Farmers: Smallholder farmers

Awards: Cup of Excellence 2008, 2010, 2011, 2012, 2013, 2014, 2015

In the cup: Plum, grilled pineapple and milk chocolate, balanced by black tea on the finish. Sweet and creamy, with great balance and structure.

This 100% Red Bourbon coffee was processed at Ubumwe washing station, which sits at 1,650 metres above sea level in the Gacurabwenge sector of Kamonyi District, in Rwanda’s Southern Province. Ubumwe washing station is privately owned by the wonderful Epiphanie Mukashyaka of Buf Coffee and her family.

Located only 20 minutes away from the capital city Kigali, the region surrounding Ubumwe washing station has very rich soil, with high levels of phosphorus, potassium, zinc, and boron. These nutrients are key in the nutrition of coffee trees, as they promote cherry ripeness and root development. Ubumwe receives cherries from approximately 500 farmers in the surrounding villages, who grow coffee at altitudes of 1,550m–1,700m above sea level.

Ubumwe’s first year of operation was in 2017, and the property includes Buf’s recently built dry mill, which is used to process all coffee produced by the company. This added control during the milling and preparation of the coffee allows for more micro-lot separation and experimentation. The property also includes a cupping lab facility, which ensures feedback provided during quality control is given to station workers in a more direct manner. Ubumwe is managed by Edoine Mugisha, who used to head operations at Nyarusiza, another washing station owned by Buf. Edoine oversees all of the operations of both the wet and dry mill.

Coffee is delivered by foot or bike to the washing station. Trucks also go to remote pick up points to pick up cherry.

HOW COFFEE IS PROCESSED AT UBUMWE WASHING STATION

- The ripe cherries are picked by hand and then delivered to the washing station either on foot, by bike, or by trucks that collect cherries from various pick-up points in the area.

- Before being pulped, the cherries are deposited into flotation tanks, where a net is used to skim off the floaters (less dense, lower grade cherries). The heavier cherries are then pulped the same day using a mechanical pulper that divides the beans into three grades by weight.

- The beans (in parchment) are then dry-fermented (in a tank with no added water) overnight for 8–12 hours. They are then sorted again using grading channels; water is sent through the channels and the lighter (i.e. lower grade) beans are washed to the bottom, while the heavier cherries remain at the top of the channel.

- The wet parchment is then soaked in water for around 24 hours, before being moved to pre-drying beds where they are intensively sorted for around six hours. This step is always done while the beans are still damp because the green (unripe) beans are easier to see. It is also always done in the shade to protect the beans from direct sunlight (which they have found helps to keep the parchment intact and therefore protects the bean better).

- The sorted beans are finally moved onto raised African drying beds in the direct sun to dry slowly over 10–20 days. During this time the coffee is sorted carefully for defects and turned regularly to ensure the coffee dries evenly. It is also covered in the middle of the day when the sun is at its hottest.

- Once at 11–12% humidity, the coffee (still in its parchment) is stored in the washing station’s warehouse in carefully labelled lots until it is ready for export. The coffee is then dry milled onsite. Here the parchment is removed, and the beans are sorted again by hand and using machinery to remove any physical defects. This is done under the watchful eye of Edouine Mugisha, who has worked with Buf since 2011. Having control over the milling of the coffee means that Buf has greater control over the quality of sorting and processing from cherry delivery right through to export.

Reviews

There are no reviews yet.