Description

Region: Kilimbi sector, Nyamasheke district, Western Province

Washing Station Altitude: 1800m above sea level

Growing Altitudes: 1600-2000m above sea level

Variety: 100% Red Bourbon

Processing: Fully Washed and sun-dried on African raised beds

Farmer Group: Approx 700 farming families deliver cherries to this washing station.

Owner: KZ Noir

In the cup: Floral honey sweetness, blackcurrant acidity and notes of dulce sugar, grilled peaches, fig, cherry. A heavy bodied coffee, that is deliciously sweet, rich and complex.

Background:

We are really excited to share this 3 bag micro lot from Cyiya washing station with you. This particular lot is heavy bodied, with a floral honey sweetness, blackcurrant acidity and notes of dulce sugar, grilled peaches, fig and cherry.

About Cyiya

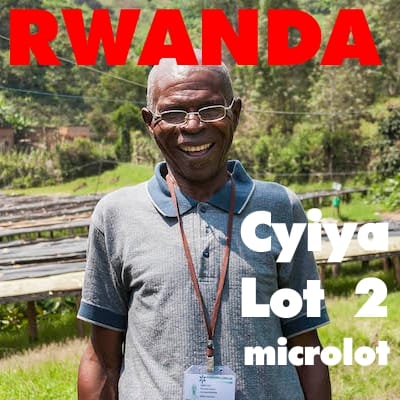

Operational since 2005, the Cyiya washing station is located at the southern end of the incredibly fertile and picturesque Lake Kivu, which is located in the Western Province of Rwanda. Sitting at an altitude of 1800 metres above sea level, Cyiya is managed by Tarzan Rumaziminsi, and supported by agronomist Jonathan. Quality is of the utmost importance at Cyiya and this is shown by their recent, 22nd place in the 2014 Cup of Excellence competition. Harvest at Cyiya typically runs from April to June with 170 workers all sorting and helping during this period. The washing station has 12 permanent workers throughout the year.

All of the producers contributing to Cyiya are very small, typically only owning less than a quarter of a hectare of land, where they cultivate an average of only 250 – 300 coffee trees each, along with other subsistence food crops such as maize and beans.

By selling their coffee to Cyiya, these small scale farmers are able to combine their harvests into large enough quantities for export and process cherries centrally. Before the proliferation of washing stations and cooperatives in Rwanda such as Cyiya, the norm in Rwanda was for small farmers to sell semi-processed cherries on to a middleman – and the market was dominated by a single exporter. This commodity-focused system – coupled with declining world prices in the 1990s – brought severe hardship to farmers, some of whom abandoned coffee entirely.

Today, it’s a different picture. Farmers who work with Cyiya have seen their income at least double, and the quality that is produced is exceptional. This is thanks to the level of care that is taken in processing this coffee.

About KZ Noir

Cyiya is owned by KZ Noir, who purchased the washing station in 2010. This is the second year we have purchased from this washing station, and our fourth year working with KZ Noir.

KZ Noir is headed up by the incredibly charasmatic, passionate and dedicated Gilbert Gatali|sprudge.com/rwanda-profiles-gilbert-gatali-of-kz-noir-22863.html. Gilbert is supported by an exceptional team of individuals, including some of the best cuppers, QC managers and agronomists in Rwanda, who are committed to quality and dedicated to improving the lives of its coffee farming community. KZ Noir takes active steps to protect the environment, using anti-erosion techniques and a special waste water treatment procedures at each of its washing stations to that ensure that processing coffee takes as little a tole on the land as possible. They also support the community of coffee farmers by providing agronomy training and sharing best practive, and by supplying organic fertilizers and pesticides, which are an essential part of producing exceptional coffee in Rwanda.

Over the past year, KZ Noir and it’s acumen fellows have been interviewing the coffee farmers that contribute cherries to their washing stations. These surveys cover a range of different demographic questions and they also use the ‘Progress out of Poverty Index’ to measure the quality of life for these farmers over time. This information helps KZ Noir measure the livelihood and needs of farmers in the different the regions it operates, and enables it to tailor and focus support where it is most needed.

Coffee Processing at Cyiya

- Cherries are hand picked only when fully ripe and then carefully sorted on delivery to the mill before being pulped that same evening using a mechanical pulper that divides the beans into three grades by weight.

- After pulping the coffee is fermented overnight (for around 12 hours) and then graded again using flotation channels that sort the coffee by weight (heaviest usually being the best), and then the coffee in parchment is soaked in water for around 24 hours.

- The washed beans are then moved from the wet fermentation tanks onto the pre-drying tables, where they are intensively sorted for around six hours. This step is always done whilst the beans are still damp because the green (unripe) beans are easier to see. It is also always done in the shade to protect the beans from direct sunlight (which they have found helps to keep the parchment intact and therefore protect the bean better).

- Next, the beans are moved onto raised drying tables in the sun for around 14 days (depending on the weather), where they are sorted again for defects, turned regularly and protected from rain and the midday sun by covers.

- The dried beans (still in their parchment) are stored in the washing station’s warehouse, in carefully labeled lots, until they are ready for export. When the coffee has been adequately rested (for at least one month) it is then sent to Rwanda’s capital, Kigali, where a dry mill removes the parchment.

- Now just coffee seeds, the coffee is sorted again by hand to remove any physical defects, bagged in 60 kilo portions, loaded into a sealed shipping container, driven to port, and shipped to us!

Reviews

There are no reviews yet.