Description

Location: Mutitu, Kirinyaga

Altitude: 1420 masl

Arabica varietals: SL-28, Ruiru 11, SL-34, Batian

Process: Washed

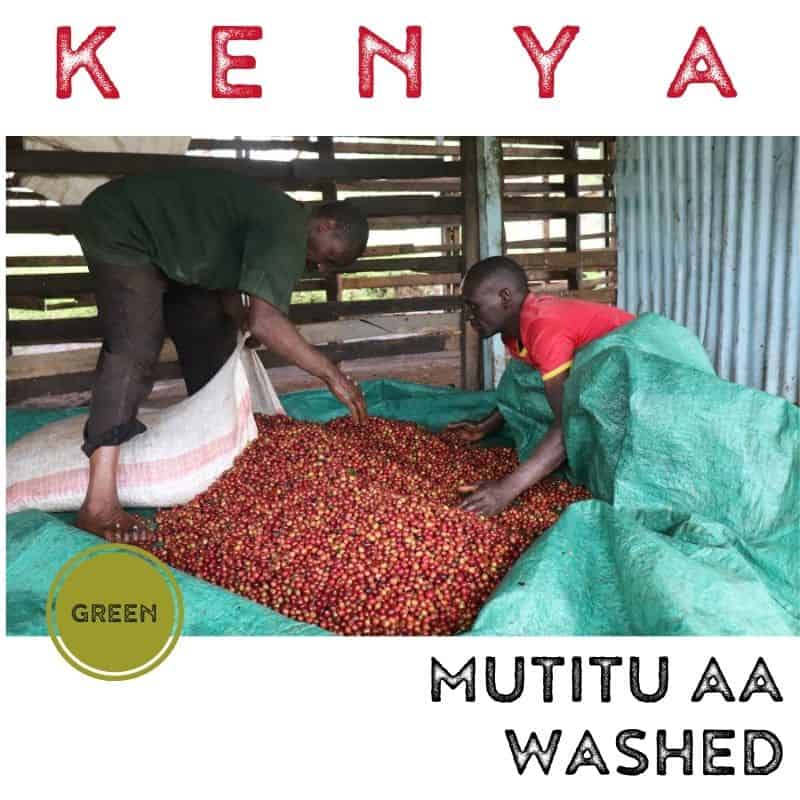

Producer: Small landholders

Processor: Mutitu factory est. 1963

In the cup: Blackcurrant, cocoa, grapefruit, honey, lime, plum and roasted hazelnut.

Mutitu factory was started in 1963 and it lies on the southern slopes of Mount Kenya, in the Kirinyaga region. The mill is used by small-hold farmers in the area. This and the adjacent regions are the premier coffee areas in Kenya, and the coffees from here are consistently among the best in the world.

LOCATION

Mutitu factory is located in Kathekiini location,Kathare location at Kirinyaga county. There are 1,250 members who deliver coffee cherries to the Mutitu factory who each have on average around ½ acre of land for coffee growing alongside macadamia, beans and maize.

SOILS AND CLIMATE

The area has rich and fertile red volcanic soil at altitudes of 1420 metres above sea level. Smallholder members of this cooperative have access to advances for farm inputs along with training in crop husbandry and land management.

PROCESSING

The coffee is handpicked by the smallholder members and delivered to the factory where it is pulped. This initially separates the dense beans from the immature ‘mbuni’s (floaters) using water floatation which means the denser beans will sink and be sent through channels to the fermentation tank.

This first stage of fermentation will last for around 24 hours, after which the beans are washed and sent to the secondary fermentation tank for another 12-24 hours. Once the fermentation process is completed, the beans enter the washing channels where floaters are separated further and the dense beans are cleaned of mucilage.

The washed beans will then enter soaking tanks where they can sit under clean water for as long as another 24 hours. This soaking process allows amino acids and proteins in the cellular structure of each bean to develop which results in higher levels of acidity and complex fruit flavours in the cup – it is thought that this process of soaking contributes to the flavour profiles that Kenyan coffees are so famed for.

The beans are then transferred to the initial drying tables where they are laid in a thin layer to allow around 50% of the moisture to be quickly removed. This first stage of drying can last around 6 hours before the beans are gathered and laid in thicker layers for the remaining 5-10 days of the drying period. The dry parchment coffee is then delivered to a private mill and put into ‘bodegas’ to rest – these are raised cells made of chicken wire which allows the coffee to breathe fully. Coffee is traditionally sold through the country’s auction system, though recent amendments to the coffee law of Kenya have brought about the introduction of direct trading whereby farmers can by-pass the auction and sell directly to speciality roasters around the world.

SUSTAINABLE FARMING

In line with the rising awareness on the need to conserve the environment, the factory has dug the waste water soak pits away from the water source where the waste water is allowed to soak in back to the soil. Currently the factory does not engage in waste water treatment. Additionally the society encourages its members to plant trees on their farms.

MANAGEMENT

Mutitu Coffee factory is run by a factory manager who oversees all activities within the factory. Together with other staff members they carry out duties such as weighing coffee, selection and grading of coffee, paying farmers and addressing farmers’ complaints.

ECOLOGY

In addition to coffee, common crops grown are banana and maize. Grevillea or macadamia trees are also planted to provide shade to the growing coffee trees.

WELFARE

Currently the factory offers farm inputs on credit and cash advances to farmers as incentives.

(Info Courtesy of Condesa)

Reviews

There are no reviews yet.