Description

District: Ruli Sector, Gakenke District Province, Northern Province

Altitude: 1800-2100 metres above sea level

Variety: 100% Red bourbon

Processing: Washed

Washing Station: Nkara

Owners: Dukunde Kawa Cooperative

Farmers: 232 Cooperative members

Awards: Cup of Excellence 2010, 2011, 2012, 2013, 2014, 2015, 2018

In the cup: Green apple, golden kiwi and peach iced tea, with crisp lemon lime acidity and dried fig on the finish. Complex and layered.

This 100% Red Bourbon lot was produced by smallholder farmers who deliver coffee cherry to Nkara washing station, the smallest of three washing stations owned by the Dukunde Kawa Cooperative. Nkara is located close to the small town of Mususa, in the Ruli Sector of Gakenke District, in Rwanda’s mountainous Northern Province.

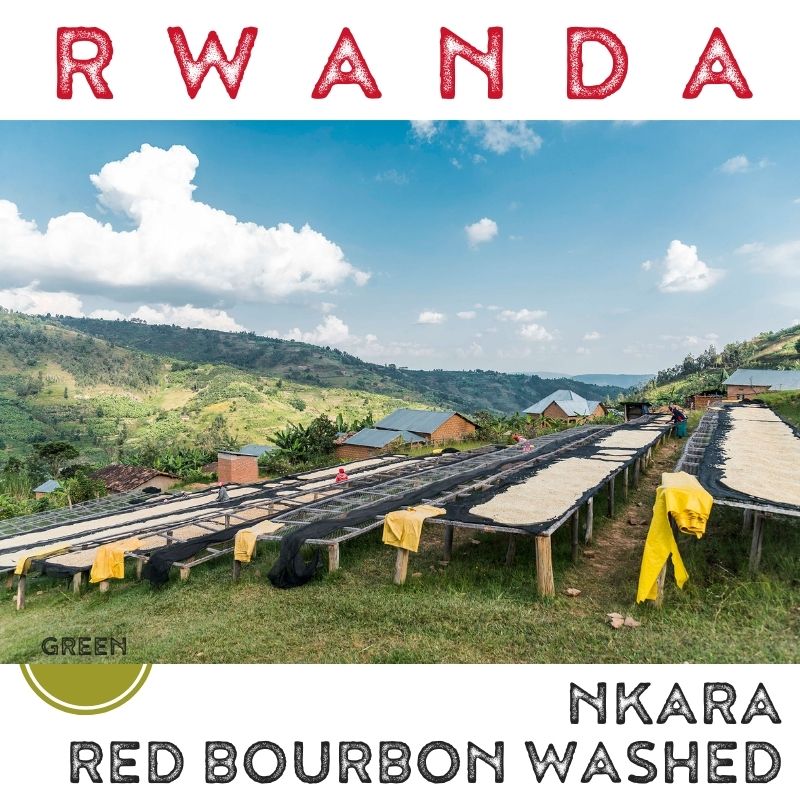

Nkara was established in 2005 and is the smallest of Dukunde Kawa’s washing stations, servicing about 232 of its members – about 22% of whom are women – who own small farms locally. The washing station sits at an elevation of 1,856 meters above sea level, overlooking a beautiful landscape of rolling green hills and rich, red earth. Quality control and day to day operations at Nkara are overseen by Michel Dusengimana, who has been the manager since 2007. He is one of the washing station’s three permanent staff members. During the season there are 26 staff members working at Nkara, who are mostly women, employed to sort the coffee during its drying stages.

The area surrounding Nkara has mineral-rich soil and a lush environment that is well suited to specialty coffee production. Typically, farms are very small – averaging just a quarter of a hectare – and are situated between 1,800 to 2,100 meters above sea level. Coffee is grown as a cash crop, alongside subsistence food crops like maize, beans and sorghum and some livestock like goats, chickens and cows.

Head here to learn more about the work of Dukunde Kawa in Rwanda.

PROCESSING AT NKARA WASHING STATION

The team at Dukunde Kawa takes a huge amount of care in processing its coffee. All members of the cooperative are trained to only select ripe coffee cherries from their trees.

- On delivery the cherries are inspected and sorted by hand to ensure only the very ripest cherries are processed. They are then sorted by weight (and any floaters are removed) by a Pinhalense machine that the washing station staff affectionately have named the ‘Umupolisi’ (police person). They are then pulped on the same day – usually in the evening – using a mechanical pulper that divides the beans into three grades by weight, with the heaviest, A1, usually having the highest cup quality.

- After pulping, the coffee is fermented overnight for around 12–18 hours and then graded again using floatation channels that sort the coffee by weight. The beans are then soaked for a further 24 hours, before being moved to raised screens for ‘wet sorting’ by hand.

- As with most washing stations in Rwanda, women do the majority of hand-sorting. This takes place in two stages – on the covered pre-drying tables and on the drying tables. Washed beans are moved from the wet fermentation tanks onto the pre-drying tables, where they are intensively sorted under shade for around six hours. The idea is that greens (unripe beans) are still visible when the beans are damp, while the roofs over the tables protect the beans from the direct sunlight.

- Next, the beans are moved onto the washing station’s extensive raised drying tables (‘African beds’) for around two weeks, where they are sorted again for defects, turned regularly and protected from rain and the midday sun by covers, ensuring both even drying and the removal of any damaged or defective beans. During this period the coffee is also turned several times a day by hand to ensure the coffee dries evenly and consistently.

- After reaching 11% humidity, the coffee is then transported to Dukunde Kawa’s purpose-built warehouse prior to final dry-milling and hand sorting at the cooperative’s dry mill.

(Info courtesy of Melbourne Coffee Merchants)

Reviews

There are no reviews yet.